Error message

Warning: file_get_contents(https://ipinfo.io/18.116.69.203/country): failed to open stream: HTTP request failed! HTTP/1.0 429 Too Many Requests in include_once() (line 654 of /home/wireterminalstre/public_html/sites/default/settings.php).Custom grips and fixtures

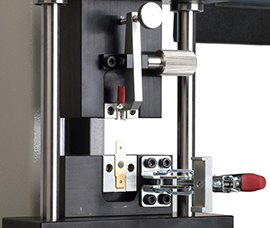

Fixtures for a wire terminal pull-off may require support beneath the barrel, or gripping the terminal blade or tongue. For pulling high-tensile strength splices apart, specific cam-design fixtures can be required. More frequently, terminals are custom designed with barrel and blade at an offset angle. These ideally require mounting as for use on a custom block fixture.

Other terminal testing includes insertion and withdrawal forces for connectors, which require accurately-aligned gripping, and easy setting up.

At Mecmesin our engineers find economic design solutions for gripping most types of wire terminal even the most awkward of shapes and sizes.

Push-fit electrical connectors must offer a firm but practical fit. Where vibration is a factor, they must especially not work free, but for maintenance they must be separable without being damaged or damaging other components. For repeatable testing of insertion and withdrawal forces, the connecting parts have to be held securely in alignment, without applying additional gripping forces in the connection.

Push-fit electrical connectors must offer a firm but practical fit. Where vibration is a factor, they must especially not work free, but for maintenance they must be separable without being damaged or damaging other components. For repeatable testing of insertion and withdrawal forces, the connecting parts have to be held securely in alignment, without applying additional gripping forces in the connection.

Mecmesin designed custom fixtures for this client to hold the naked terminal parts and the spade connectors in a way that allowed for rapid test sample exchange and maximum throughput.

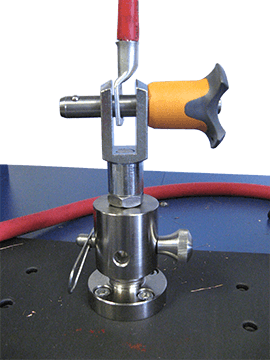

A major manufacturer of wire harnesses and connectors approached us for a cost-effective solution to strength testing cables of different diameters and welded joints, up to 1 kN. Standard cam grips to this rating proved too heavy and bulky.

A major manufacturer of wire harnesses and connectors approached us for a cost-effective solution to strength testing cables of different diameters and welded joints, up to 1 kN. Standard cam grips to this rating proved too heavy and bulky.

Mecmesin designed narrow-profile lever cam grips for the required application, enabling rapid sample insertion and maximum throughput on a minimum requirement test system.

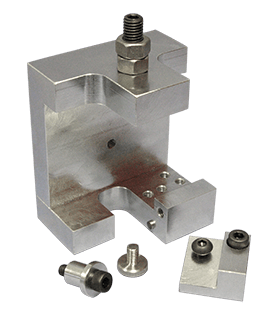

A major European wire harness manufacturer required special fixtures for testing its cables with copper barrel terminals above 5 kN. Mecmesin designed and made custom fixtures for both loop and bolt-end terminators. For use on one of our twin-column testers, this ensured correct and secure gripping, where wedge grips alone could not imitate their purposed fixing.

A major European wire harness manufacturer required special fixtures for testing its cables with copper barrel terminals above 5 kN. Mecmesin designed and made custom fixtures for both loop and bolt-end terminators. For use on one of our twin-column testers, this ensured correct and secure gripping, where wedge grips alone could not imitate their purposed fixing.

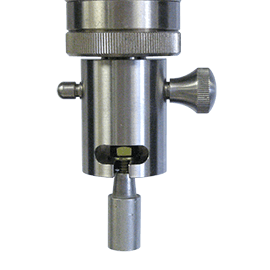

A major European wire harness manufacturer required a special fixture for testing its cables with expected pull-off forces of up to 10 kN. Secure gripping of the cable remains essential, but at these loads and with the specific cable gauge, a unique 5 cam grip had been found to deliver consistent results. The grip self-tightens and holds the cable without damage to accurately measure the true pull-out force of the crimped terminal component. Mecmesin designed and manufactured grips to this specification.

A major European wire harness manufacturer required a special fixture for testing its cables with expected pull-off forces of up to 10 kN. Secure gripping of the cable remains essential, but at these loads and with the specific cable gauge, a unique 5 cam grip had been found to deliver consistent results. The grip self-tightens and holds the cable without damage to accurately measure the true pull-out force of the crimped terminal component. Mecmesin designed and manufactured grips to this specification.