Error message

Warning: file_get_contents(https://ipinfo.io/3.137.164.107/country): failed to open stream: HTTP request failed! HTTP/1.0 429 Too Many Requests in include_once() (line 654 of /home/wireterminalstre/public_html/sites/default/settings.php).Pull test standards and methods

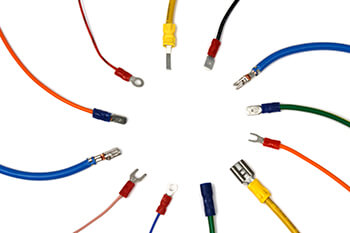

Background

The quality of a crimp joint depends on the mechanical strength of the joint as well as its electrical conductivity. If results from pull force tests are within an allowed range, it assures that the proper crimp force has been applied during the crimping process.

The quality of a crimp joint depends on the mechanical strength of the joint as well as its electrical conductivity. If results from pull force tests are within an allowed range, it assures that the proper crimp force has been applied during the crimping process.

This is crucial as enough force must be applied to break down the layer of non-conductive oxides that may build up on the stripped conductor and the plating on the inside of the terminal. This is necessary to provide a good metal-to-metal contact. If this does not occur, electrical resistance can increase.

Overcrimping a crimp termination will reduce the circular area of the conductor and thereby increase electrical resistance.

Crimp joint testing (commonly known as "pull testing") ensures the integrity of the final product but, more importantly, it ensures the effectiveness of the crimping tool itself since it can be calibrated according to test results. Calibration is best carried out in response to Statistical Process Control (SPC) analysis which can be gathered from data obtained by pull testers.

Standards and methods

There are many standards to adhere to and each manufacturer or user might have different requirements to fulfil. But one thing in common is that international and industry standards all prescribe procedures for testing the tensile strength of wire terminals in a repeatable manner.

It is essential that there is no jerking or sudden application of force. This is the reason why standards state that there should be a 'constant rate of pull' and most define a pull rate at which tests should be performed. The only practical way to achieve repeatability for pull force tests is to set a speed by using a motorised pull tester such as the WTST range of testers.

Although standards define a minimum acceptance-value for the pull force according to the wire diameter and AWG conductor size, it is of greater importance to the manufacturer and user to know that joints can definitely sustain higher loads. So an increasing axial force is applied to the connection until either the terminal and wire separate or the wire breaks.

Pull and Break

Directly pulling the wire joint until destruction at a constant rate (typically 25 to 50 mm/min) is the most commonly adopted test method and is known as 'Pull and Break'. It is performed by using a motorised pull tester in which the peak force to separate the terminal from the wire is measured. This value is then compared to the table of minimum pull forces outlined in the standard in order to determine a pass or fail of the connection.

Other test methods call for more in-depth procedures:

When carrying out a pull test most companies do not remove the insulation sleeve around the crimp. However, the IPC/WHMA, UL, USCAR and VW standards specifically require that the insulation support is rendered mechanically ineffective by opening it up. Certain other standards (e.g. VW) provide a higher pull force value if the insulation support is left in place around the crimp.

- Pull and Return

A non-destructive test whereby the terminal is pulled to a specified force and then the force is removed. - Pull and Hold

A non-destructive test whereby the terminal is pulled to a specified force and held for a specified period of time. The force is then decreased to zero. - Pull, Hold and Break

A destructive test whereby the terminal is pulled to a specified force and held for a specified period of time. It is then pulled further until either the terminal and wire separate or the wire breaks.